Your innovative Partner in North America!

RUD group and Caldwell Inc. channel their market power and pool their expertise in lifting and lashing equipment. Customers in the USA and Canada profit from a complete spectrum of product from a single source, as well as from even more quality, service, and customer focus. The RUD lifting and lashing means as well a lifting point, sets innovative standards that characterize the entire lifting industry.

Whether for welding or bolting, more than 700 tested lifting and lashing points up to 250 tons of load capacity reduce the handling costs and increase the work safety of our customers.

The comprehensive portfolio of innovate solutions in mechanical engineering and plant engineering for tool handling, hydropower and hydraulic steelwork meet the highest performance standards and quality requirements. With the RUD machines and systems, the “conveyor and drives” division creates the perfect mechanical engineering solution for every conveyor technology scenario. The easy ergonomic operation of your tool handling saves time and costs. The solutions in plant engineering and the drive technology. The RUD TECDOS components in plant engineering guarantee sustainable solutions under difficult conditions (heat, cold, ice).

The comprehensive portfolio of innovate solutions in plant engineering and mechanical engineering for power generation, the bulk solids sector and tool handling meets the highest performance standards and quality requirements.

Company

Lifting means

RUD lifting points and slings stand for reliability, health & safety at work and quality “Made in Germany”. Thanks to the comprehensive range of lifting points and slings available, loads weighing 100 kg to 250 tonnes can be lifted, moved and transported safely. 700 different tested RUD lifting point variants in welded and forged versions are available for all lifting technology applications.

End components

How do I connect the lifting means with the load or the loaded goods?

product details

Chains

What has to be taken into account when selecting chains (length, material, diameter etc.)?

product details

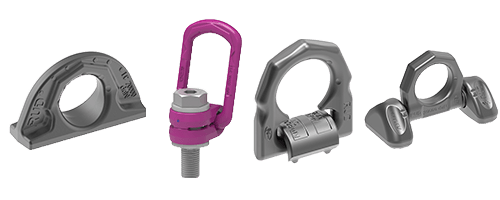

Lifting points

What must be taken into account when choosing the right lifting points?

product details

Load securing

During the transportation of machines or components, high forces often act on the load. For safe transportation, it is important to apply the necessary retaining forces reliably in order to keep the load on the load bed.

Lashing points

Lashing points connect the load bed with the lashing chain. Lashing points from RUD are available both in weldable and in boltable versions.

product details

Shortening elements

Shortening elements make manual fast-shortening possible for the subsequent ideal adjustment of the tensioning elements.

product details

Chains

The ICE Lashing Chain replaces grade 8 of the next largest nominal thickness and has an up to 60% higher breaking load (significant weight savings, improved ergonomics, faster attachment and increased safety through improved material properties).

product details

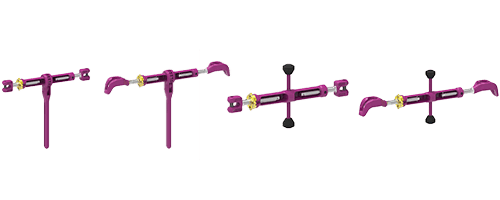

Tensioning elements

Tensioning elements make fast and easy pre-tensioning possible. In addition, RUD tensioning elements have a practical mechanical locking device and an anti-theft device.

product details

Lashing points

Lashing points connect the loading area with the lashing chain. Lashing points from RUD are available in both weldable and boltable versions.

product details

Identification tags

Identification tags from RUD contain information about the respective lashing chain (reliable lashing force, pre-tension force etc.). In addition, it can be used to check the main set-down criteria of the chain (Gauge function).

product details